Have you experienced the frustration of having a sling tag fall off of your sling? Unfortunately, it’s a fairly common occurrence.

The American Society of Mechanical Engineers (ASME) code B30.9 requires each lifting sling to have a permanently affixed tag to indicate important information. This code is meant to ensure that each sling is working within and complying with professional and responsible requirements. (Learn more about the requirements of ASME B30.9 here.)

If the sling tag falls off, there is no way to know for sure the capacity of the sling, so for safety reasons and by code it must either be recertified in order to be used again or be thrown away. Using slings without tags creates a safety hazard for workers and a significant liability issue for all parties involved. Using a sling without a sling tag risks your jobsite, your job, and your company – it is just not worth the risk.

The problem is that traditional sling tags fall off. When tags fall off, users are required to get another sling that is properly tagged. If a properly tagged sling is not available, the options are to either shut the jobsite down or operate unsafely. Neither is a good option!

What are traditional options to attach your sling tags?

There are several traditional options for attaching sling tags:

Aircraft cable inserted into sleeve before swaging: This is the traditional choice. The tag is affixed to a wire rope sling using a small cut (e.g. 5”-10”) of a small diameter wire rope that is inserted into either the base or top of a sleeve before it is swaged.

Aircraft cable inserted into sleeve before swaging: This is the traditional choice. The tag is affixed to a wire rope sling using a small cut (e.g. 5”-10”) of a small diameter wire rope that is inserted into either the base or top of a sleeve before it is swaged.- Aircraft cable w/ a duplex sleeve: This method involves a small cut of a small diameter aircraft cable and is affixed to the sling using a duplex sleeve and a crimper. Typically, this method is used after the sling has been fabricated, such as retagging a sling in the field or after a load test.

- Cable Zip Ties

- Cordura or other sleeves: This method of tagging uses a synthetic sleeve affixed to the sling. This method is more expensive and not as durable as traditional sling tags.

- Textured nylon: Textured nylon is a sturdy material, but it can take a long time to sew and requires two departments in the sling shop to make. Also, it can become vulnerable through time and weather conditions, resulting in the tag becoming eligible and the subsequent safety problems.

Is there a sling tag option that will not fall off?

Until recently the answer has been no–every sling tag falls off.

That all changed when Etched introduced The Tube Tag to the market in 2019.

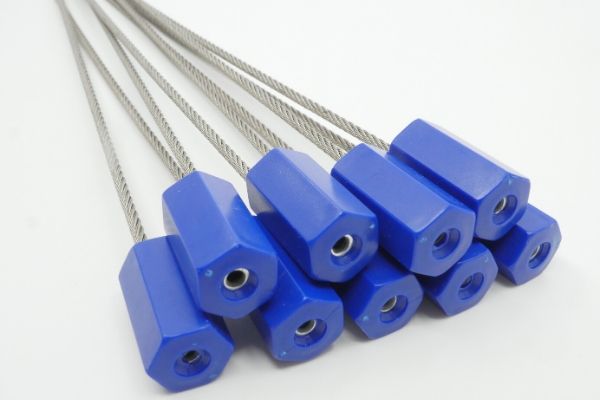

The Tube Tag is a 4-sided, ultra-durable product identification tag that fully captures the metal rope of a sling so it cannot become detached from it.

Another benefit of The Tube Tag is that, because it has 4 distinct sides, it can hold more information than other tags, including the company’s logo, the lifting capacity of the equipment, and the product’s safety regulations–and whatever other information the client wants to add!

Each Tube Tag is customized to meet the client’s specific needs and can be manufactured to accommodate any diameter of cable.

The Tube Tag’s essential advantage is that it cannot come off, since it completely captures the wire rope. It is compliant with ASME regulations and it provides a hassle-free assurance and peace of mind. No more job sites shutting down due to missing sling tags. No more frustration and lost time and money due to missing sling tags.

If you’re tired of your sling tags falling off, contact us today to learn more about The Tube Tag.

Aircraft cable inserted into sleeve before swaging

Aircraft cable inserted into sleeve before swaging